Anti-leak tapes

Posted by admin on April 6, 2022 in Other news

Which Anti-leak tapes fit your needs?

At Solastape we sell different kinds of tapes to fix a leak onboard your vessel. These tapes can solve leakage problems quickly and easily. But which anti-leak tapes fit your needs best? In this article we will tell you all about our Spray Stop tape, our Spray Control tape and our Pipe Repair tape.

Spray Stop tape

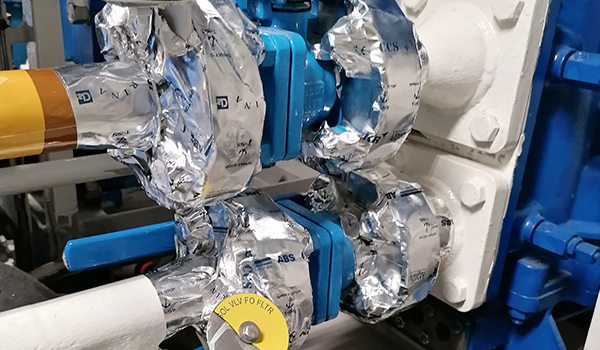

Spray Stop tape, or anti-splash tape, by T-ISS is one of our best-known products! And for good reason; it’s the best and most certified anti-splashing tape on the market. The high-tech laminated multilayer aluminum tape prevents dangerous spray-outs of hazardous liquids in tubing systems. This high-tech laminated multilayer aluminum tape has been designed by safety specialists in order to prevent spray-outs of hazardous liquids (oil/fuel) from tubing systems. These liquids can cause extremely dangerous situations like fires, explosions, or other dangerous situations.

As you can imagine, spray-outs in engine rooms, for example, can be highly dangerous. Looking at SOLAS regulations, appropriate protection needs to be installed on these tubing systems. This makes perfect sense because when it comes to it, our Spray Stop tape can save lives. This is why all of our tapes meet the SOLAS regulations. Also good to know: according to SOLAS regulations, ships should apply appropriate protection to prevent leakage/splashing of flammable oil from FO, LO hydraulic, and other systems.

The tape has a maximum pressure of 15 bar and a maximum temperature of +160 ºC continuously and +200 ºC shortly. The shelf life is 3 years.

Spray Stop tape 50+

Our Spray Stop tape 50+ has the same qualities as the normal Spray Stop Tape but is even stronger. Standard Spray Stop Tape holds pressure up to 15 bar. Spray Stop Tape 50+ extends this limit to 50 bar. This means the tape is suitable for tubing systems that transport liquids under high pressure.

Spray Control Sealing tape

Want to upgrade the safety of your pipeline systems that contain chemicals? With Spray Control Sealing tape you make your surroundings a lot safer. Other than our regular Spray Stop Tape, you can use the Spray Control Sealing tape with chemicals. This way, Spray Control prevents damage to humans, machinery, and pipes. How? Simply apply the tape on flanges & valves at chemical plants. The pre-leak detection helps save unnecessary expenditure on maintenance and repairs.

Pipe Repair tape

T-ISS Pipe Repair is a compact package that contains all necessary items to repair leakages in an instant. Pipe Repair Tape is a specially developed resin-coated glass fiber cloth. The fiberglass cloth tape is impregnated with a water-activated resin prior to packaging. To use the Pipe Repair Tape, knead the putty and place it over the leakage of the pipe. Massage it on the surface using gloves. Unpack the tape and soak it in water. Wrap the tape around the pipe and continue to smoothen with wet gloves until the tape stops bubbling.

The normal setting time is approximately 20 minutes, depending on the temperature. Furthermore, this repair product sets even underwater! Therefore, it is ideal to use in difficult/wet applications.

Interested in our anti-leak tapes? Feel free to contact us or ask for a quotation via T-ISS right away!